MACHINE CONSTRUCTION

• Meehanite Castings, fine grain and high-density cast iron using the superior Meehanite process yields superior vibration dampening and improved surface finish and tool life, as well as greater wear resistance on the ground way surfaces of this heavy-duty CNC lathe.

• Precision C-3 double-nut ballscrews ensure accuracy in repeatability and positioning

SPINDLE

• 30 HP heavy-duty spindle motor for high metal removal efficiency

• Infinitely variable spindle speeds from 6 - 500 rpm in 4-automatic gear ranges

• Hardened and ground A2-11 spindle nose (A2-15 & A2-20 spindles are optional)

• Alloy Steel Hardened & Precision Ground Gears provide for smooth power transmission

• Spindle with 6” bore (9”, 10”, & 12” options) is supported by oversized precision bearings

WAYS

• Turcite-B anti-friction coating on saddle and cross slide for improved accuracy & wear

• Automatic adjustable metered lubrication system for ballscrews and ways, with low lube alarm

• Hardened & Precision Ground Longitudinal Single-Vee Prism & Box Way for high rigidity

• Center mounted Z-Axis ballscrew for accurate tracking and smooth non-binding operation

• Cross slide is a dovetail way design

FEATURES

• Automatic 4-way toolpost standard, 8 & 12 station vertical turrets are available

• Full splash guard for chip and coolant containment

• Link-Belt style rear discharge chip conveyor included

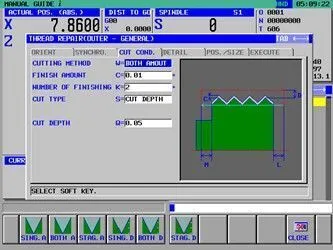

• Inch/Metric threading, left or right-hand threading, single or multiple start threading

• Built in high-capacity coolant system to flush away chips and extend tool life

• Large fluorescent worklight

• 3-light machine condition display lamp

• Heat exchanger for electrical cabinet

• Inspection Report on accuracy to CNS 94 and B7001 standards included

• Instruction Manual, Tools and Toolbox with hand tools and lube gun included

Capacity & Dimensions-

Swing over Bed 67”

Swing over Cross Slide 48”

Bed Width 31.88”

Spindle-

Spindle Motor Horsepower 30 HP (22 kW Fanuc)

Spindle Speed 6-640 rpm in 4-automatically selectable gear ranges Gear Ranges 4-infinitely variable speed ranges

6-35 rpm, 19-112 rpm, 70-350 rpm, 226-500 rpm

Spindle Bore 6” (9”, 10”, and 12” Optional)

Spindle Nose A2-11 (Optional A2-15 / A2-20 spindle nose)

Axis-

X-Axis Cross slide travel (w/standard 4-position turret) 32.6”

X-axis Ballscrew / Servo Motor 40 mm diameter,10mm pitch / 5.3-HP (4kw) Servo motor

Z-Axis travel 39.37” (chuck and turret type may reduce travel)

Z axis Ballscrew / Servo Motor 63 mm diameter,10 mm pitch / 5.3-HP (4kw) Servo motor

X and Z axis Rapid Feed Rate 196”/min

X and Z axis Cutting Feed Rate 118” /min

Minimum input unit 0.0001” (0.001 mm = 40 millionths of an inch)

Tailstock- No Tailstock with this machine

Tool Turret -

Turret Tool Stations (10 & 12 station turrets optional) 4-Station tool turret with any mix of ID & OD tools

OD Tool Size 1.57” X 1.57”

ID Tool Holder Bore (4-ID toolholders included) (1.97”)

Specifications-

Machine Dimensions – 67” swing capacity L x W x H 167” x 99” x 84”

Coolant system 1.7-HP (1.275 kW) coolant pump

Electrical needs - Fanuc 0i-TF, Drives & Motors 220 vac ±5%, 3-Ph, 60-Hz

Warranty – 1-Year Machine 2-Year FANUC control and drives

Machines need a stable 220 Volts, 3 Phase Please use appropriate transformers or voltage stabilizers.

Specifications are subject to change for improvement without notice.

We use cookies to improve your experience. Privacy Policy.