Standard Accessories:

Fanuc 0i-TF Plus

Two step gear transmission

4 jaws manual chuck

W axis cross rail up & down driven by servo motor and reducer

Cross rail up & down hydraulic clamping in any position

Ram spindle two steps gear transmission

Axial servo motor abnormal overload protection function on all axes

Double feedback system on all axes

2 head stations plus 12 tool pockets of tool storage

Hydraulic system

Pneumatic system

Centralized guide ways lubrication system

Coolant system and tank with 420 liter capacity

Full enclosure guarding system

Spindle cooling system

Recycling collectors for lubrication on 3 axes

Heat exchanger on Electric cabinet

Finish and alarm lamp

Operator panel

Work light

Wash gun for chip washing down

Air flush coolant system

RS-232 interface

MPG remote handwheel

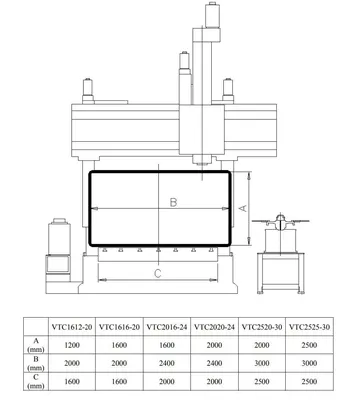

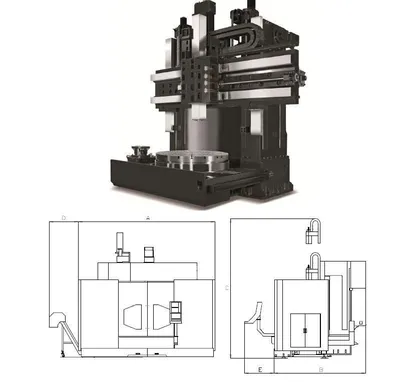

VTC2020

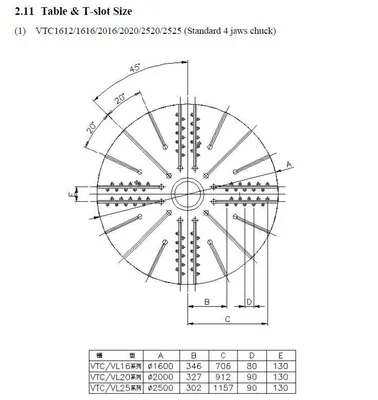

Table Diameter mm(in) 2,000 (78.7)

Max. Swing diameter mm(in) 2,400 (94.4)

Max. Turning diameter mm(in) 2,400 (94.4)

Max. Turning height mm(in) 2,000 (78.7)

Max. height from Table to Ram nose mm(in) 2,200 (86.6)

X axial travel (Head movement) mm(in) -1010~1,380 (-39.7~54.3)

Z axial travel (Head stock movement) mm(in) 1250 (49.2)

Cross rail travel mm(in) 1500 (59.1)

Table

Table speed rpm 2~200

Table driven motor (30min/cont.) kW(HP) 45/37 (60.3/49.6)

Max. Table torque Nm(lb-ft) 26,000 (19,176)

Number of table speed range 2

Clamping slots table load kg(lbs) 18,000 (39,600)

Spindle Ram:

Ram section mm (in.) 226 (8.9)

Ram spindle motor power (30min./cont.) kW(HP) 15/11 (20.1/14.8)

Spindle bearing diameter mm (in.) 115 (4.5)

Ram spindle speed rpm 1600

Max. Spindle torque Nm(lb-ft) 304 (224)

Feed rate:

Rapid feed rate of X m/min. (in./min) 10 (394)

Rapid feed rate of Z axis m/min. (in./min) 8 (315)

Cutting feed rate of each axis m/min. (in./min) 2 (78.7)

Ball screw diameter mm

X axis mm(in) 63mm (2.5")

Z axis mm(in) 50mm (2")

W axis mm(in) 63mm (2.5")

X axis servo kW 4

Z axis servo kW 7

W axis servo kW 7

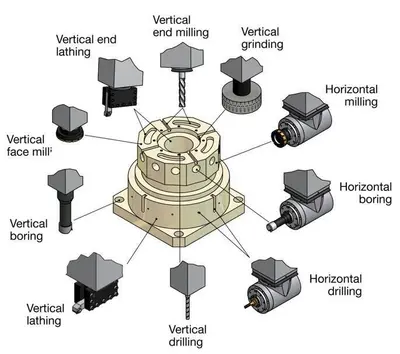

Tool magazine:

ATC capacity 2 heads + 12 pockets

Tool change mode Pick up

Tool change time (Tool to Tool) sec. 12

Max. tool length mm (in.) 300 (11.8)

Max. tool weight kg (lbs) 15 (33)

Turning tool holder type WELE

Milling tool holder BBT50

Machine accuracy:

Positioning accuracy in X & Z axes mm(in.) +/-0.007/500(0.0002/19.6)

Repeatability in all axes mm(in.) 0.010(0.0002)

Indexing axial positioning accuracy arc sec 30”

Indexing axial repeatability arc sec 15”

Coolant equipment:

Coolant tank Liter (Gallon) 420 (132)

Coolant pump HP 1.5

Pneumatic requirement:

Air resource Mpa 0.6

Electrical Reqirement

Power requirement 220V, 60 Hz 80 kVA

Space requirement:

Machine length (Approx.) mm(in.)

Machine width (Approx.) mm(in.)

Machine height (Approx.) mm(in.) 5,940 (233.8)

Machine weight (Approx.) kg(lbs) 42,000 (92,400)

We use cookies to improve your experience. Privacy Policy.