Quick and Simple Navigation featuring Easy to Learn, User-Friendly Controls

Ability to Easily Toggle Between the TOYOPUC TOUCH

Overlay and Native Fanuc Operation Screens

Built in Reporting that that Monitors Energy Usage, Productivity, Tool Life and more

A Navigation Bar Present On All Screens; Allowing Users To Move Throughout Multiple Sections

Automated Maintenance Reminders With Detailed Instructions On Performing Inspections

The Ability for Maintenance Staff To View The HMI On A Tablet Or Mobile Device Using TeamViewer

A “Diagnostic Data Collection” Button To Backup Data Such As Ladder Logic, Parameter and Offsets

A Simplified Repair Process with Step-Through Procedure for Common Issues such as ATC Recovery

Ability to Record/Send Video/Upload Tool Images With a USB To JTEKT Operator

On Board Storage of all Machine Maintenance and Operation and Tooling Manuals

Lock Out Control Features Based on Defined Criteria for

Operators/Programmers/Maintenance

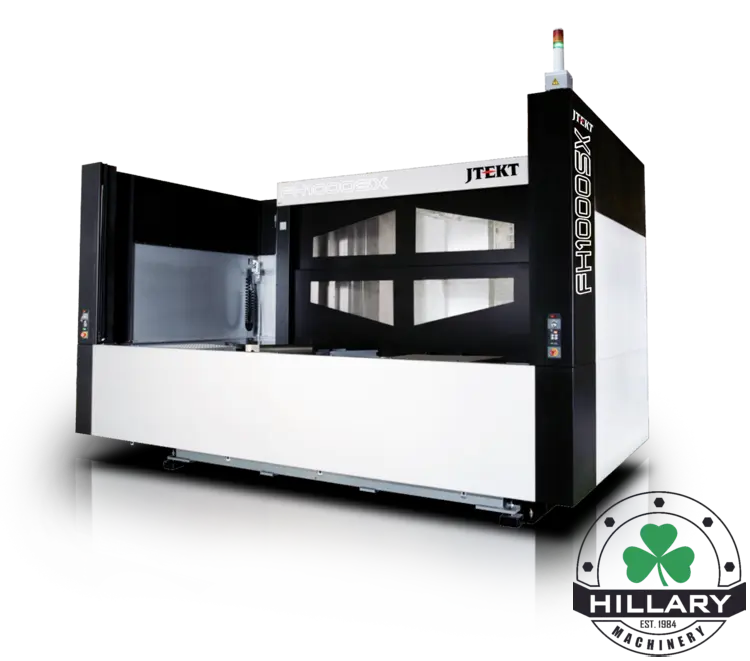

Standard

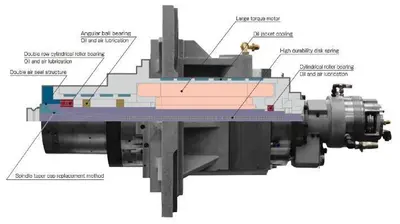

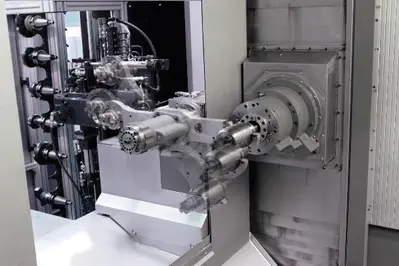

8,000 RPM High Torque Integral Spindle 74HP 1202NM Torque

Big Plus modification for All Series Spindles

High Pressure Coolant-Thru-Spindle (Up To 1,000 PSI) 8.5 Gpm

Pump with Relief Valve Calibrated for 500 ~ 1,000 PSI

360,000 Degree NC Positioning B Axis Table

Overhead Coolant Shower

Hand Held Splash Gun at APC Load Station

FANUC 31iMB with Toyopuc Touch 19" Touch Screen HMI Display

Upgrade Control Features - 8MB Memory - 48 Work Offsets - 200 Tool Offsets

High Speed Control Features - 1000 Block Look Ahead Function with High Speed Processor

OP Supporter Package - Tool Life Management - Adaptive Control

We use cookies to improve your experience. Privacy Policy.