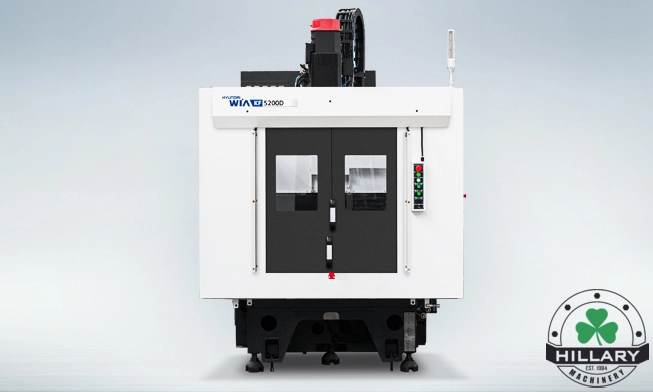

KF5200D has been designed for high productivity, high speed machining, and precision accuracy. The travel column design with an integral 180 degree turning table allows the operator to load/unload the part while machine is running with the pallet. The large span of the column increases the machine rigidity for heavy cutting. 42position tool magazine provides the tool storage required for multiple part run.

TRAVEL:

X axis travel 29.9"

Y axis travel 20.5" (520mm)

Z axis travel 22.4" (570mm)

Table top to spindle nose 7.9" ~ 30.3" (200 ~ 770mm)

ATC Door to spindle center 3.90" ~ 24.37" (99 ~ 619mm)

TABLE:

Table size 2 x 29.9" x 20.5" (860 x 570mm)

Allowable load 2 x 772 lbs (350kg)

Table Tap size (36) M16 / 3.9" pitch (100mm)

Table change time 5.5 sec

SPINDLE:

Spindle Speed 12,000 rpm

Spindle Taper CAT #40

Pull Stud (Retention Knob) 45°

A.C. spindle motor (S3 15%) 24.8 HP (18.5 kW)

Spindle torque (S3 15%) 87 lbf.ft (118 N.m)

AUTOMATIC TOOL CHANGER:

Number of Tools 42

Tool Shank CAT # 40

Max. Tool Dia. Ø3.1" (Ø80mm)

with empty adjacent pockets Ø4.9" (Ø125mm)

Max. Tool Length 11.8" (300mm)

Max. Tool Weight 17.6 lbs (8kg)

Tool change time (tool to tool) 1.8 sec

Tool change time (chip to chip) 3.9 sec (Adjacent) / 10.0 sec (Remote)

MOTION:

X / Y / Z axis rapid traverse rate 1,654 / 1,654 / 1,654 IPM (42 / 42 / 42m/min)

Max. Cutting Feed 394 IPM (10,000 mm/min)

Least command increment .0001" (.001mm)

GENERAL:

Machine Height 121.9" (3,096 mm)

Floor Space (L) with rear chip conveyor & Tank 197.0" (5,003.2 mm)

※Floor Space (L) without chip conveyor & Tank 159.0" (4,038 mm)

Floor Space (W) 88.8" (2,255 mm)

※Floor Space (W) without chip conveyor & Tank 84.2" (2,139 mm)

\Machine weight 18,519 lbs (8,400 kg)

Power required 34 kVA / ??? amp @ 220V

Voltage Required 205 - 235 Volts / 3 Phase

Specifications are subject to change for improvement without notice.

STANDARD FEATURES

Hyundai Wia Fanuc i series - Smart Plus Control

Max. 12,000 rpm Direct Driven spindle

Powerful 24.8 HP (18.5 kW) spindle

High precision spindle with double row angular contact ball bearings

CAT #40 Spindle Taper

Central hydraulic supply system : 2 x 3 ports (2 hydraulic ports and 1 air port)

Spindle orientation

Spindle override

290 PSI through the spindle coolant.

Massive Meehanite cast iron bed

Double Pre-Tensioned Ball screws

Fast 1,654 IPM (42 m/min) X, Y and Z axis rapid speed

Rigid tapping

Custom Macro (User Definable)

Pick-up type ATC and 42 Tool magazine

Portable Manual Pulse Generator

Program and data protection key switch

Telescopic way covers

Large separate coolant tank

Work light

3 color tower signal light

Instruction manual, parts list, and electrical drawings

Fanuc operator and maintenance manuals

One-year machine warranty: Parts and Labor

Two-year control and motor warranty: Parts and Labor

We use cookies to improve your experience. Privacy Policy.