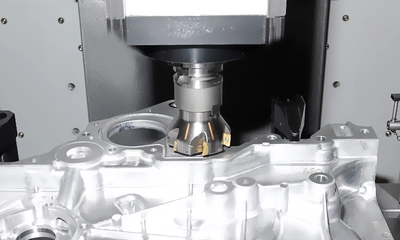

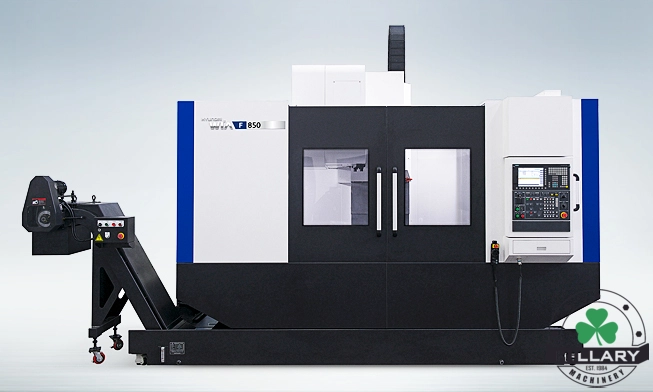

The F850 is designed by Hyundai WIA with years of experience and the latest technology, maximizes productivity and provides stiffness and rigidity. F850 offers Hyundai value at an economical and affordable price, and provides high productivity and profitability and matches typical of complex, contoured geometry associated with die/mold and medical production.

PDF Catalog https://www.hillaryinc.com/index_htm_files/hyundai-kf5600-machiningcenter.pdf

■ SPECIFIACTIONS

TRAVEL:

X / Y axis travel 62.99" / 33.46"

Z axis travel 22.83"

Table top to spindle nose 5.91" ~ 28.74"

Column to spindle center 36.7"

TABLE:

Table size 70.9" x 33.5"

Allowable load 2,205 lbs

Table T slot spacing x width (7) x 3.93" x 0.71"

SPINDLE:

Spindle Speed 12,000 rpm

Spindle Taper BCV #40

Pull Stud (Retention Knob) 45°

A.C. spindle motor (30min) 14.8 HP

Spindle torque (30 min) 51.6 lbs.ft

AUTOMATIC TOOL CHANGER:

Number of Tools 30

Tool Shank BCV #40

Max. Tool Dia. Ø 3.54"

with empty adjacent pockets Ø 5.91"

Max. Tool Length 11.8"

Max. Tool Weight 17.6 lbs

Tool change time (tool to tool) 2.0 sec

Tool change time (chip to chip) 4.7 sec

MOTION:

X / Y axis rapid traverse rate 1,417 / 1,417 IPM

Z axis rapid traverse rate 1,417 IPM

Max. Cutting Feed 591 IPM

Least command increment .0001"

GENERAL:

Machine Height 130.0"

Floor Space (L) with side chip conveyor & tank 186.3"

Floor Space (W) 132.0"

Machine weight 33,069 lbs

Power required 65 kVA / ??? amp @ 220V

Voltage required 205 - 235 Volts / 3 Phase

Specifications are subject to change for improvement without notice.

■ FEATURES

• Hyundai Wia Fanuc i Control

• Max. 12,000 RPM Direct driven Spindle

• Powerful 11 kW (14.8 HP) (30min) spindle motor

• Spindle Oil chiller system

• BCV 40 taper

• Fast 36 m/min (1,417 IPM) X,Y and Z axis rapid traverse

• Roller Guide Way

• ATC 30 Tools

• “Y” shape ribbed column structure

• Bed Flushing Coolant System

• Metal plate coupling on all axes

• Pendant operating panel

• Auto Power Off

• 290 PSI through the spindle coolant

• Remote Manual Pulse Generator

• Spindle override 50% to 150% (10% Unit)

• Massive Meehanite cast iron bed

• Double Pre-Tensioned Ball screws

• Slanted telescopic way covers

• Chip Conveyor (33.5” discharge height)

• Flood coolant with large separate coolant tank

• 3 color tower signal light

• Full enclosure splash guard

We use cookies to improve your experience. Privacy Policy.