The CNC Turning Center HD2600LE Series, designed by HYUNDAI WIA with years of expertise and the latest technology, is designed to maximize productivity by enhancing both technical performance. All axes of HD2600LE are designed with Box Guideway and providing more heavy duty cutting performance.

■ SPECIFICATIONS

CAPACITY:

Swing over bed Ø29.5”

Swing over carriage Ø19.7”

Maximum turning diameter Ø19.7”

Maximum turning length 30.7”

Bar Capacity Ø3.2” (Ø 81mm)

SPINDLE:

Chuck size 10”

Spindle bore Ø3.6”

Spindle speed 3,500 rpm

Spindle nose A2-8

A.C. Spindle Motor (30 min. rating) 35 HP

Maximum spindle torque (30 min. rating) 541.4 lbf-ft.

TRAVEL:

X axis travel 10.4”

Z axis travel 32.7”

X / Z axis rapid traverse rate 945 IPM / 1,181 IPM

X / Z axis ball screw diameter Ø 1.26” / 1.57”

X axis guideway span 14.17”

Z axis guideway span 17.32"

TURRET:

Number of tools 12

Turning tool shank size 1” (25mm)

Boring bar diameter Ø 2”

Turret index time (1 step) 0.15 sec

Turret clamping force (35bar) 13,576 lbs.

PROGRAMABLE TAIL STOCK (Tow-along type):

Tailstock quill diameter Ø 3.94”

Tailstock quill stroke 4.72”

Tailstock body stroke 32.7”

Tailstock spindle taper MT #5

Maximum tailstock quill thrust 2,180 lbs.

COOLANT and HYDRAULIC SYSTEM:

Coolant tank capacity 47 gal (180 liter) /

Hydraulic tank capacity and required oil [8 gal] / VG32 or CB32

Lubrication tank capacity and required oil 0.5 gal / G68

GENERAL:

Machine Height 72.8”

Floor Space (L) with chip conveyor 188.4”

Floor Space (W) 70.9”

Machine weight 13,116 lbs.

Power required 27 kVA / 71 amp @ 220V

Voltage required 205 - 235 Volts / 3 Phase

Specifications are subject to change for improvement without notice.

■ FEATURES [HD2600LE]

• Hyundai Wia Fanuc i series controller

• Ø19.7” Max. turning diameter

• 30.7”Turning length

• Ø3.2” (Ø 81mm) Bar capacity

• Powerful 35 HP (26kW) spindle motor

• Torque 541.4 lbf-ft. (734 N.m)

• 10” chuck

• A2-8 spindle nose

• RPM 3,500 spindle

• Servo Turret (12 station) [10 station_opt.]

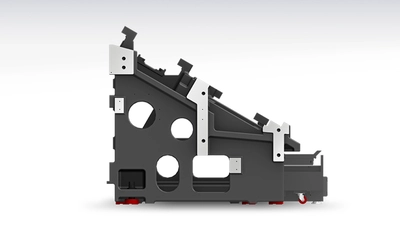

• 30° slanted one-piece bed structure

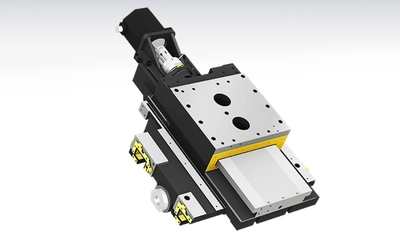

• Box Guideways

• 944 IPM (24m/min) X and 1,181 IPM (30m/min) Z axis rapid traverse

• Manual Tool setter

• Tool size: □ 1” / Ø 2” (□25mm / Ø50mm)

• Programmable Tail Stock (Tow-along type)

• 87 PSI coolant system (290 PSI-opt)

• Massive Meehanite cast iron bed

• Double Pre-Tensioned Ball screws

• Rigid tapping

• Program and data protection key switch

• Chip Conveyor (47” discharge height)

• 3 color tower signal light

• Full enclosure splash guard

We use cookies to improve your experience. Privacy Policy.