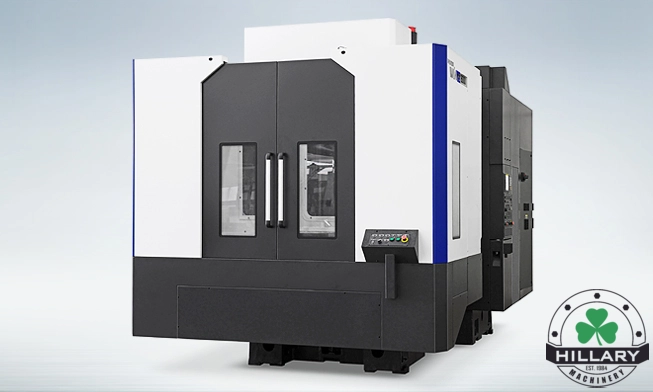

The HS8000II is manufactured using the latest state-of the-art manufacturing technology and is one of the most versatile members of HYUNDAI-WIA’s outstanding line of CNC Horizontal Machining Centers. The HS series has been designed to meet the demanding requirements found in today metal working market.

FEATURES

Fanuc 31i-B Control

Max. 10,000 RPM built-in spindle [6,000rpm_H/Torque]

BBT #50 spindle taper

Powerful 60.3 HP (45 kW) spindle motor (S3 15%) [73.8 HP (55 kW) _H/Torque]

Spindle torque 459.5 lbf.ft at 470 RPM [595.2 lbf.ft _H/Torque at 355rpm]

Max. 2-4,409 lbs Load capacity

Ø57.9"x H63" (Ø1,470 x H1,600mm) Working size

90 ATC driven by servo motor

1,969 ipm (50m/min) X, Y and Z axis rapid speed

Large Linear Roller guide ways

1,015 PSI through the spindle coolant

Oil jacket spindle cooler

Massive cast iron bed

Pre-Tensioned & Double Anchored Ball screws

Qualified edge locators

High precision taper cone type pallet clamping system

Pallet rotation at pallet loading station

Portable Manual Pulse Generator

Program and data protection key switch

Slanted telescopic way covers

Chip Conveyor (42.9" discharge height)

3 color tower signal light

We use cookies to improve your experience. Privacy Policy.