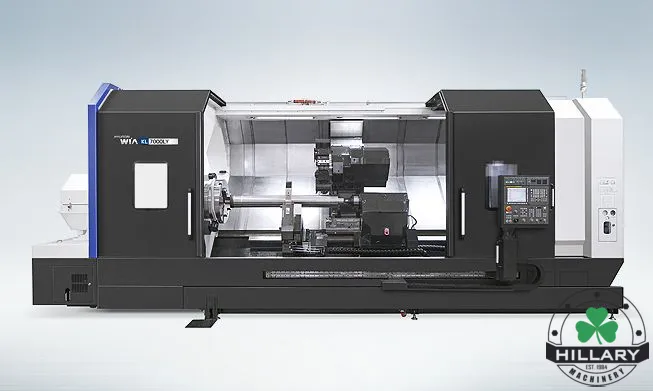

The KL7000LY features a flat bed design which was developed using finite element analysis (FEA) to absorb vibration and minimize thermal growth, ensures a stable platform for powerful precise cutting capabilities. Box guideways offer improved rigidity due to the increase surface contact with the guideway and can applicable for a variety of applications.

• Fanuc 32i Series Control

• 1,500 RPM / [700 RPM on KL8000LY] (No Chuck)

• 3 Step / [2 Step] gear box embedded head stock

• Powerful 60HP (45kW) spindle motor

• Spindle orientation

• 87psi High Pressure Coolant

• Double Pre-Tensioned Ball screws

• Fast 472 IPM (12m/min) X, Z and 394 IPM (10m/min) Y axis

• Manual Tool Setter

• 12 Station Turret

• Programmable built-in tail stock (Tow-along type)

• Standard Dead Center (MT #6)

• (2) Steady Rest Preparation

: Customer needs to get a steady rest which is being required for the part

• Right Side Hinge Type Chip Conveyor (47” discharge height)

• 3 color tower signal light

• Rigid tapping

• 163 Gal (620 ℓ) Coolant Tank

• Standard Hyd. Unit - 60Bar (870psi) /16.6 Gal (63 ℓ) Tank

• Instruction manual, parts list, and electrical drawings

• Fanuc operator and maintenance manuals

• Two-year machine warranty: Parts; and 1 Year Labor

• Two-year control and motor warranty: Parts and Labor

We use cookies to improve your experience. Privacy Policy.