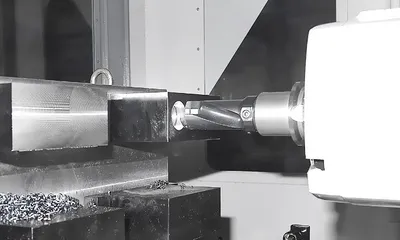

The KH63G is manufactured using the latest state-of the-art manufacturing technology and is one of the most versatile members of WIA’s outstanding line of CNC Horizontal Machining Centers. The KH63G has been designed to meet the demanding requirements found in today metal working market.

• Fanuc 31i-BControl

• 8,000 RPM spindle

• Powerful 26kW (35 HP) spindle with 2 speed geared head

• High precision spindle with double row angular contact ball bearings

• CAT # 50 Spindle Taper

• 1 degree index table (Opt 0.001 Degree)

• Oil jacket spindle cooler

• 1,000 PSI through the spindle coolant.

• Massive Meehanite cast iron bed

• Wide induction hardened and precision ground guide ways

• Low friction fluoroplastic resin mating way surfaces

• Double Pre-Tensioned Ball screws

• Fast 20m/min (787 IPM) X,Y and Z rapid traverse

• Rigid tapping

• Custom Macro (User Definable)

• Cam Type Double Arm ATC 90 Tools

• Automatic pallet changer with (2) Tapped pallets

• Qualified edge locators

• Pallet rotation at pallet loading station

• Portable Manual Pulse Generator

• Program and data protection key switch

• Metered piston distributor lubrication

• Telescopic way covers

• Full enclosure splash guard

• (2) screw type conveyors in the machine

• Chip Conveyor (32” discharge height)

• Flood coolant with large separate coolant tank

• Work light

• 3 color tower signal light

• Instruction manual, parts list, and electrical drawings

• Fanuc operator and maintenance manuals

• Two-year machine warranty: Parts and 1 Year Labor

• Two-year control and motor warranty: Parts and Labor

We use cookies to improve your experience. Privacy Policy.