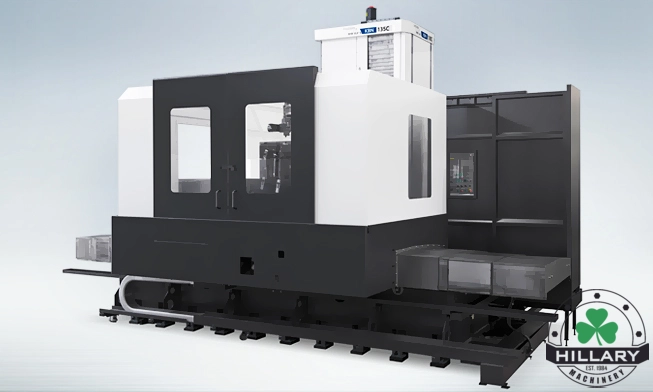

The KBN135C is manufactured using the latest state-of-the-art manufacturing technology and is one of the most versatile members of HYUNDAI-WIA’s outstanding line of CNC Horizontal Boring Mills. The KBN135C has been designed to meet the demanding requirements found in today metal working market.

Brochure

http://machine.hyundai-wia.com/upload/product/pdf/KBN135C(en).pdf

• Fanuc 31i-AControl

• Column moving type construction

• 2,500 RPM spindle

• Powerful 26kW (35 HP) spindle with 3 speed geared head

• High precision spindle with double row angular contact ball bearings

• CAT 50 Spindle Taper

• Spindle orientation

• Spindle override 50% to 150%

• Oil jacket spindle cooler

• 290 PSI through the spindle coolant.

• Massive Meehanite cast iron bed

• Wide induction hardened and precision ground guide ways

• Low friction fluoroplastic resin mating way surface on all axis

• Double Pre-Tensioned Ball screws

• Fast 7m/min (276 IPM) X, and 10m/min(393 IPM) Y,Z and 8m/min(315 IPM) W rapid traverse

• Rigid tapping

• Custom Macro (User Definable)

• Cam Type Double Arm ATC 60 Tools

• Portable Manual Pulse Generator

• Program and data protection key switch

• Metered piston distributor lubrication

• Telescopic way covers

• screw type conveyors in the machine

• Chip Conveyor (45” discharge height)

• Flood coolant with large separate coolant tank

• Work light

• 3 color tower signal light

• B-Type coolant protect cover

• Instruction manual, parts list, and electrical drawings

• Fanuc operator and maintenance manuals

• Two-year machine warranty: Parts and 1 Year Labor

• Two-year control and motor warranty: Parts and Labor

We use cookies to improve your experience. Privacy Policy.